Welcome to our websites!

-

Eight sides (4000-10500 pcs/hr)

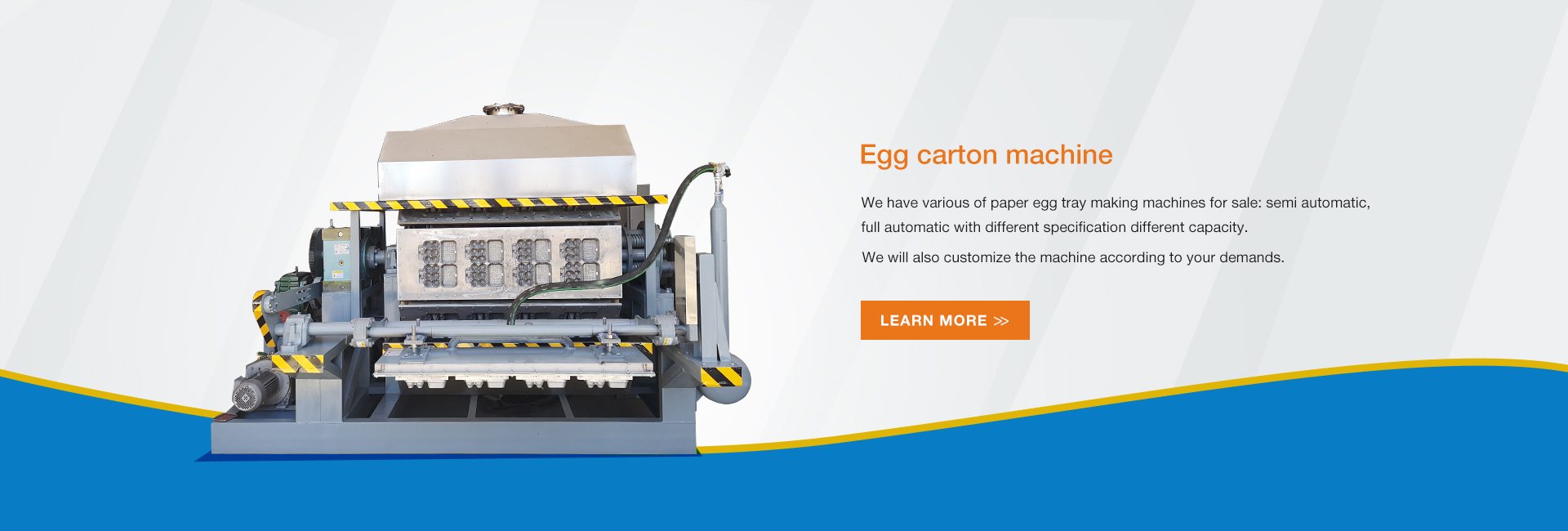

The automatic rotary paper tray production line is composed of a pulping system, a forming system, a drying system and a packing system. Pulping: It is the process of mixing the raw materials with water. Then you can get the slurry that is dried to form the egg trays. Molding: The process is that using negative pressure and vacuum absorption turn the slurry to egg trays. You can make egg trays, egg boxes, apple trays and so on with the egg tray machines by changing different moulds. Drying: It basically involves drying the wet semi-finished products by using egg tray drying line. Good drying process can lead to minimal losses of poorly-formed trays. There are metal and brick egg tray drying line.