Trending Products Paper Pulp Molding Process - Twelve sides (5500-7500 pcs/hr) – Pantao

Trending Products Paper Pulp Molding Process - Twelve sides (5500-7500 pcs/hr) – Pantao Detail:

Equipment overview

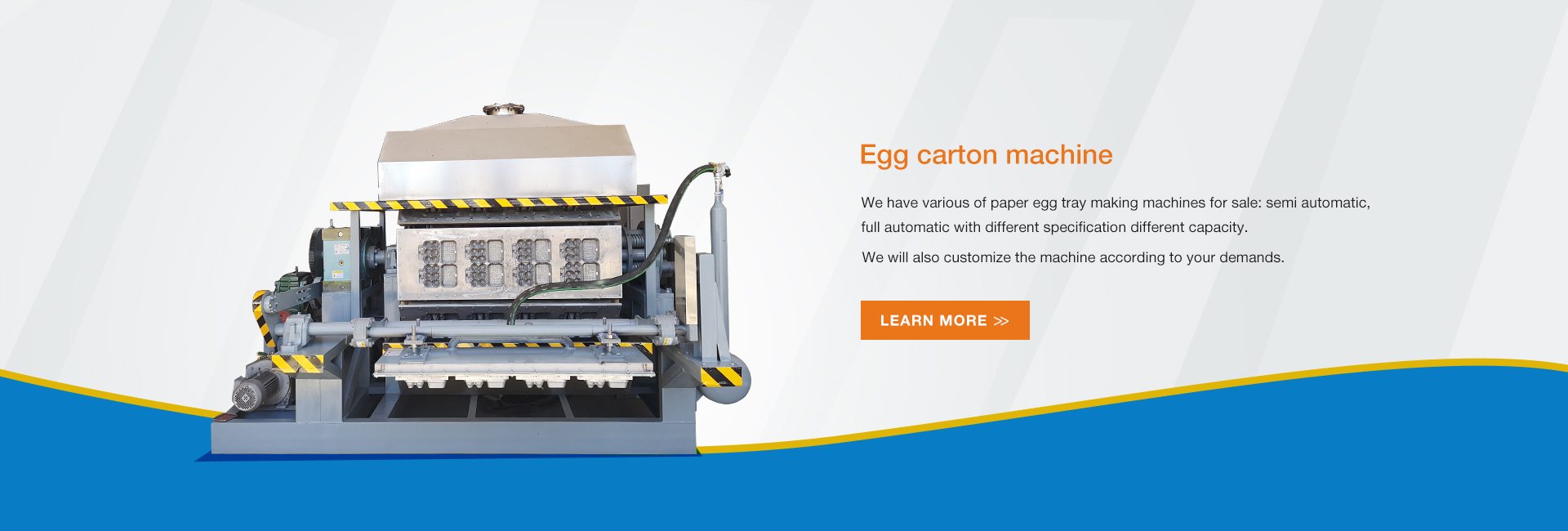

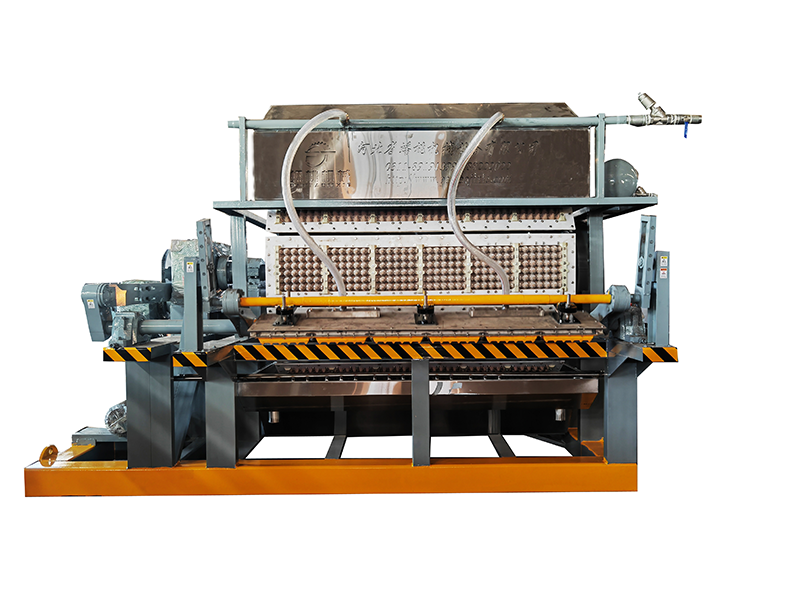

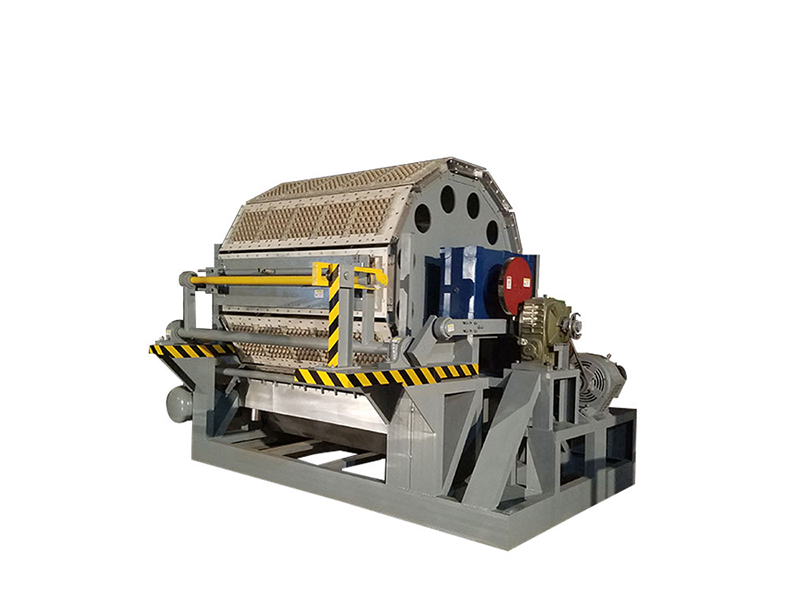

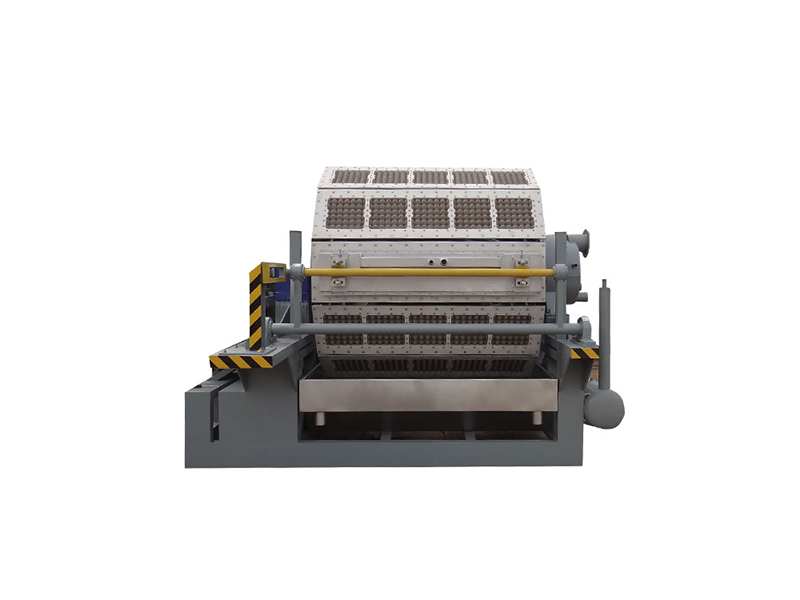

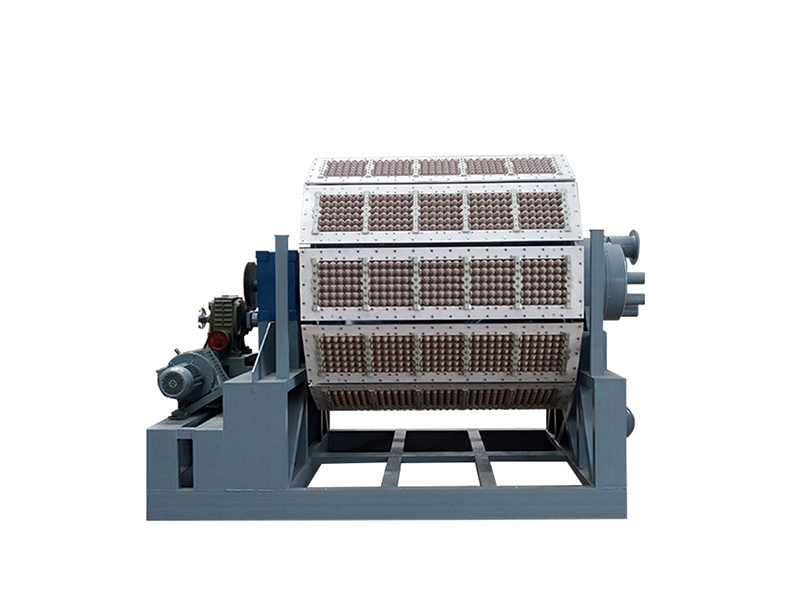

This equipment is a twelve-side drum forming machine. The equipment consists of forming templates, transfer templates, worm reducers, motors, intelligent control appliances, high-precision dividers and solenoid valves. The drive motor drives the worm reducer to drive the divider to make the equipment move intermittently.

YZ-12X6000 (5-12) egg tray making machine is mainly used for pulp molding products such as egg trays, coffee cup trays, fruit trays, medical trays, etc.

The drying method is generally natural drying.

YZ-12X7000 (6-12) full-automatic paper pulp egg tray making machine can be produced automatically. This automatic egg tray machine can produce various specifications of egg trays, paper coffee cup holders, fruit trays, medical trays and other pulp molding products.

Parameters

| Model | YZ-12X6000(5-12) | YZ-12X7000(6-12) |

| Capacity/hour | 5500-6500pcs | 7000-7500pcs |

| Template size | 1790MMX470MM | 2100MMX470MM |

| Number of molds | 60+6 boxes | 72+6 boxes |

| Operating mode of forming machine |

Rotary adsorption molding |

|

| Molding cycle |

17-24 times/minute |

|

| Power | 178kw | 245kw |

| labour | 5-6 person/shift | 6-7 person/shift |

| Paper | 425 kg/hour | 490 kg/hour |

| Water | 1275kg/hour | 1470 kg/hour |

| Product height that can be produced |

55mm |

|

| Drying method |

A:Traditional brick dryer B:Metal multi-layer dryer Heat energy can be used: coal, natural gas (LNG), diesel, liquefied petroleum gas( LPG), heat transfer oil, steam and other heat energy |

|

| 1. The capacity of the equipment is calculated based on the production of 30 egg trays with a size of 300*300mm and a dry tray weight of 70g.

2. Various specifications of equipment can be customized according to customer requirements. |

||

Product detail pictures:

Related Product Guide:

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for Trending Products Paper Pulp Molding Process - Twelve sides (5500-7500 pcs/hr) – Pantao , The product will supply to all over the world, such as: Bulgaria, Romania, Burundi, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.