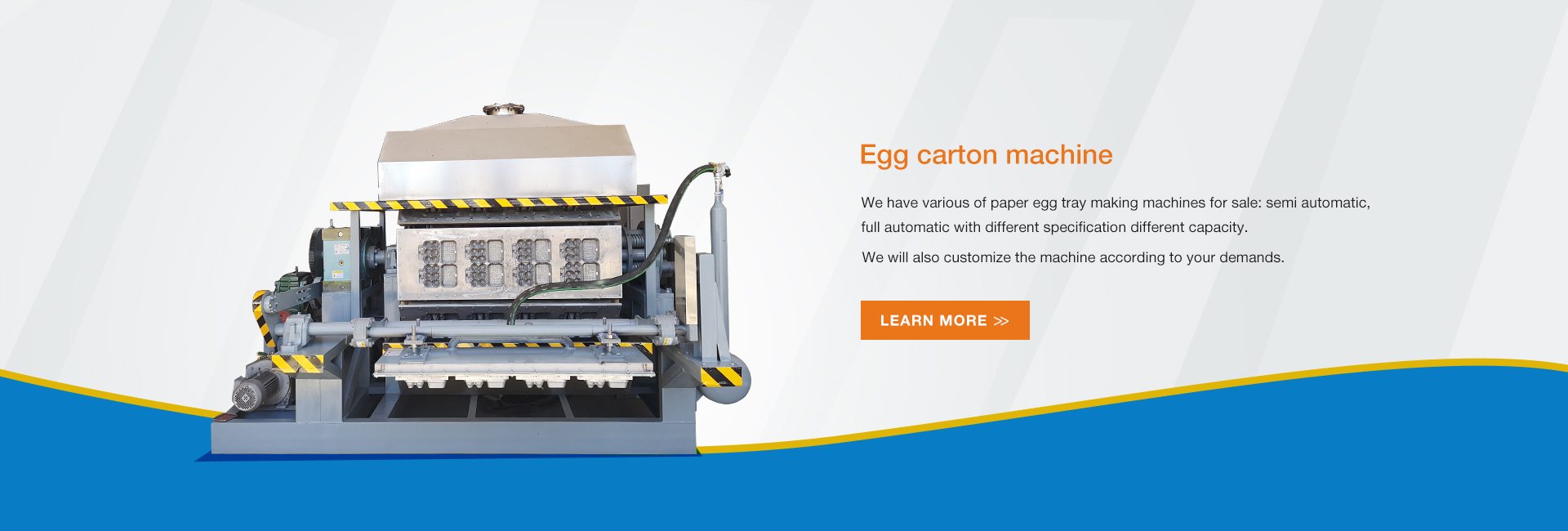

Quality Inspection for Automatic Paper Making Machine - Eight sides (4000-10500 pcs/hr) – Pantao

Quality Inspection for Automatic Paper Making Machine - Eight sides (4000-10500 pcs/hr) – Pantao Detail:

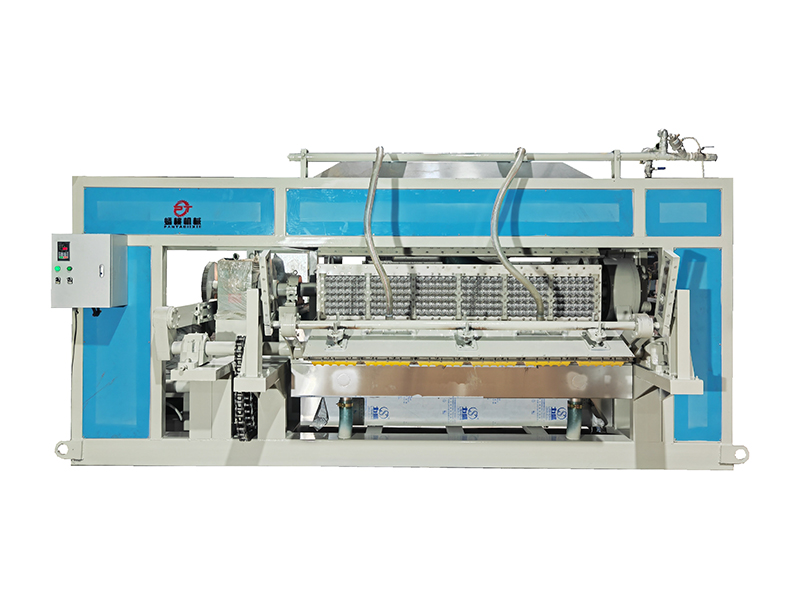

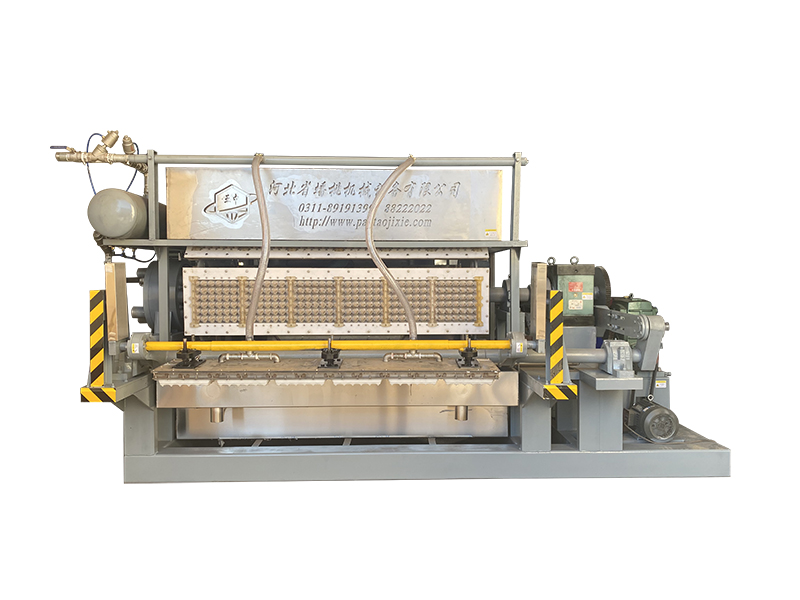

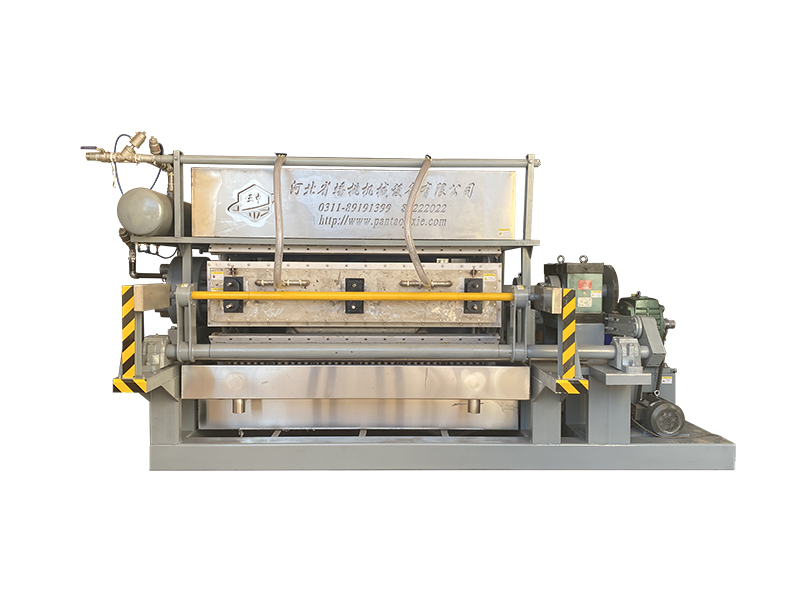

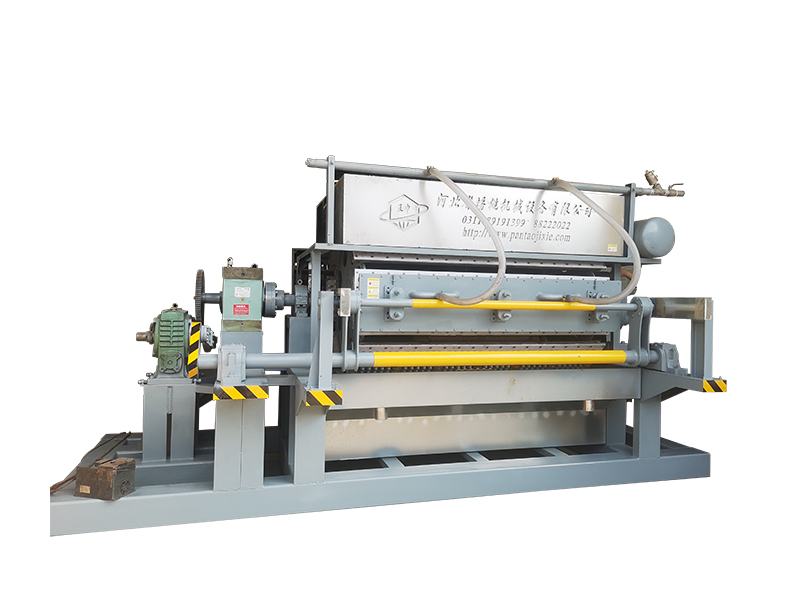

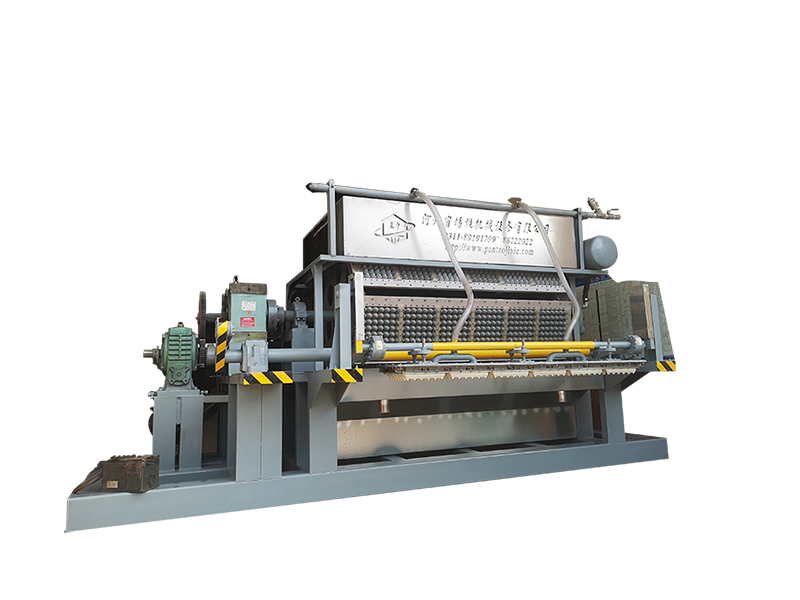

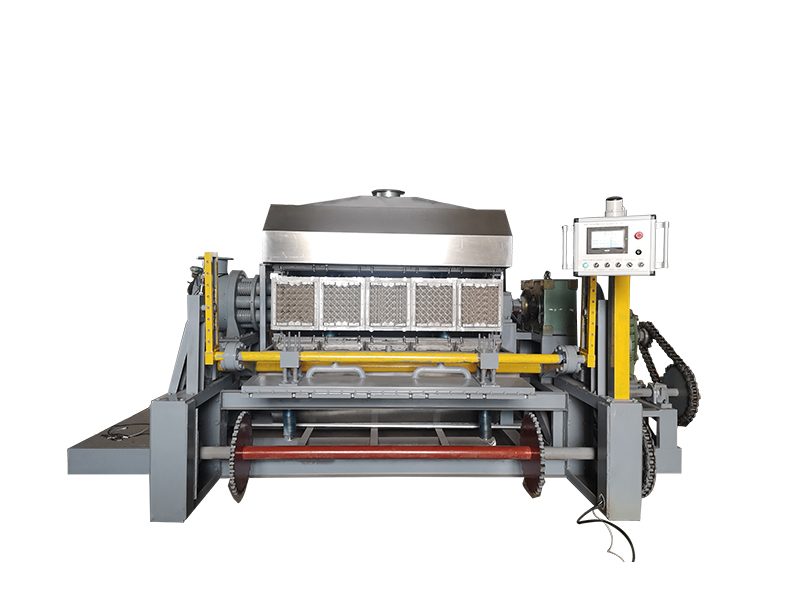

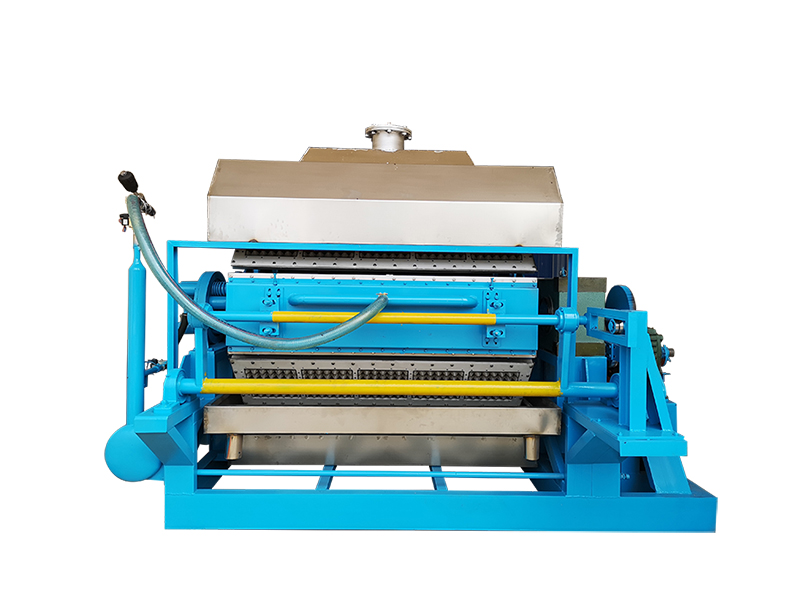

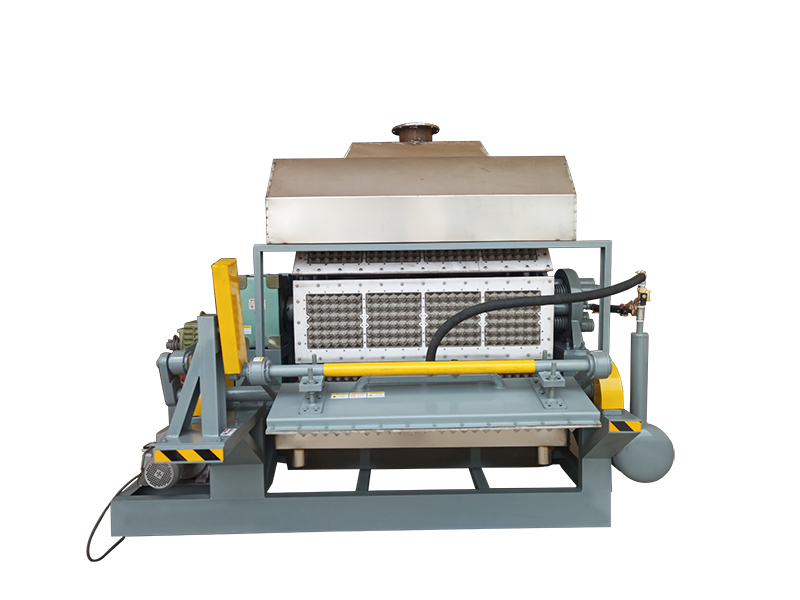

Equipment overview

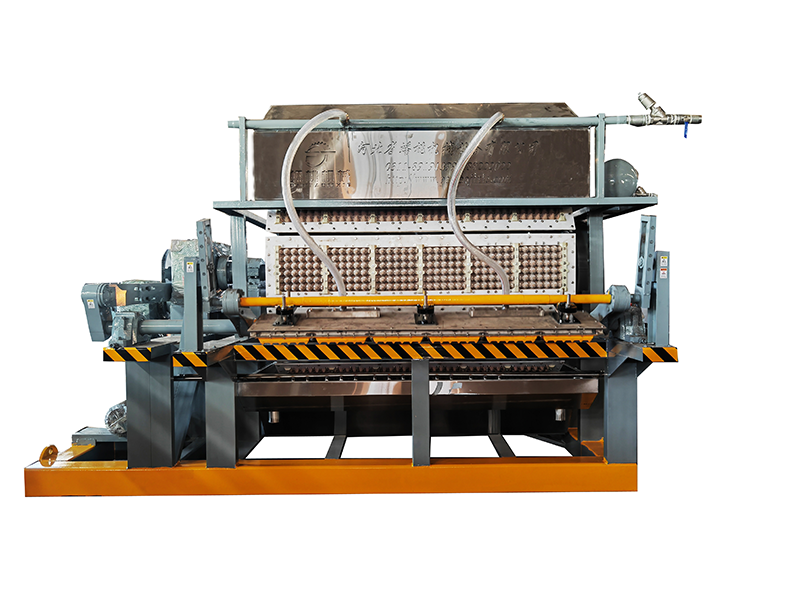

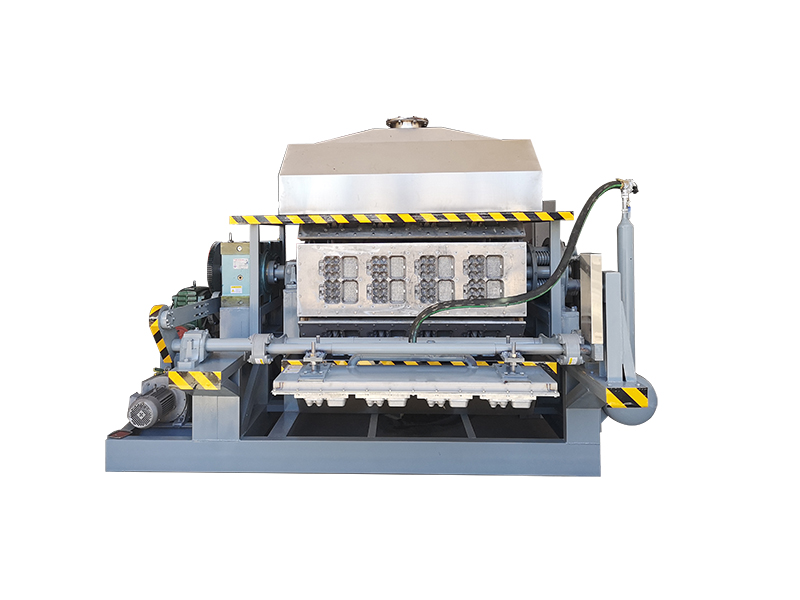

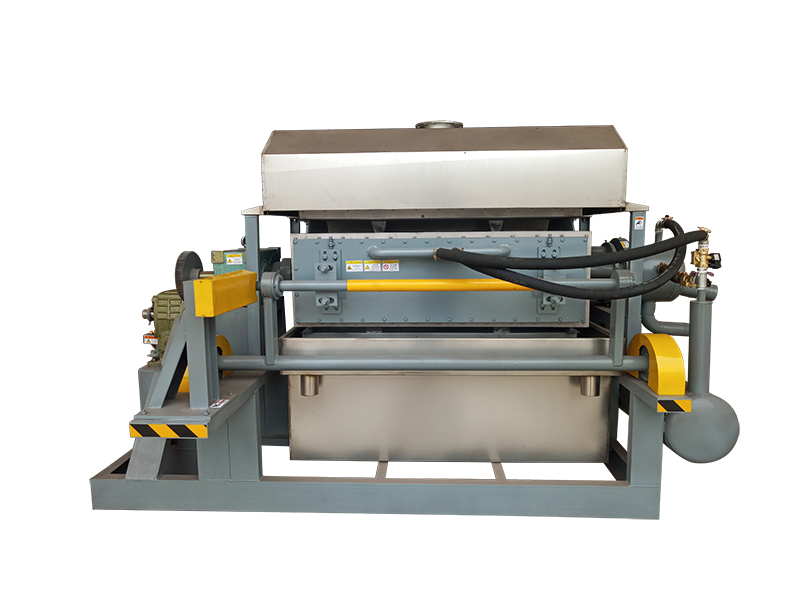

This equipment is an eight-sides rotary egg tray forming machine, which consists of forming templates, transfer templates, worm reducers, motors, intelligent control electrical appliances, high-precision dividers, solenoid valve and other components. The drive motor drives the worm reducer to drive the divider to make the equipment move intermittently.

YZ-8X4000 (4-8) egg tray machine is mainly used to produce pulp molding products such as egg trays, coffee cup trays, fruit trays and medical trays.

The drying method is generally natural drying.

YZ-8X5000 (5-8) egg tray production machinery mainly produces pulp molding products such as egg trays, coffee cup trays, fruit trays and medical trays. The drying method is generally natural drying or dryer.

YZ-8X6000(6-8) full-automatic egg tray production line can produce automatically. This egg tray equipment can produce various specifications of egg trays, paper coffee cup holders, fruit trays, medical trays and other pulp molding products.

YZ-8X8000 (8-8) full-automatic paper egg tray pulp molding machine can produce automatically. This egg tray equipment can produce various specifications of egg trays, paper coffee cup holders, fruit trays, medical trays and other pulp molding products.

Advantages

1. Large output and high return on investment.

2. High degree of automation

3. Energy saving

Parameters

| Model | YZ-8X4000(4-8) | YZ-8X5000(5-8) | YZ-8X6000(6-8) | YZ-8X8000(8-8) |

| Capacity/hour | 4000-5000pcs | 5000-6500pcs | 6000-7500pcs | 8000-10500pcs |

| Template size | 1470MMX470MM | 1790MMX470MM | 2100MMX470MM | 2900MMX470MM |

| Number of molds | 32+4 boxes | 40+5 boxes | 48+6 boxes | 64+8 boxes |

| Operating mode of forming machine |

Rotary adsorption molding |

|||

| Molding cycle |

15-22 times/minute |

|||

| Power | 129kw | 150kw | 153kw | 200 kw |

| labour | 4-5 person/shift | 5-6 person/shift | 5-6 person/shift | 6-7 person/shift |

| Paper | 380 kg/hour | 425kg/hour | 459 kg/hour | 500 kg/hour |

| Water | 1140 kg/hour | 1275 kg/hour | 1377 kg/hour | 1500kg/hour |

| Product height that can be produced |

60mm |

|||

| Drying method |

A:Traditional brick dryer B:Metal multi-layer dryer Heat energy can be used: coal, natural gas (LNG), diesel, liquefied petroleum gas( LPG), heat transfer oil, steam and other heat energy |

|||

| 1. The capacity of the equipment is calculated based on the production of 30 egg trays with a size of 300*300mm and a dry tray weight of 70g.

2. Various specifications of equipment can be customized according to customer requirements. |

||||

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Quality Inspection for Automatic Paper Making Machine - Eight sides (4000-10500 pcs/hr) – Pantao , The product will supply to all over the world, such as: Hungary, Adelaide, Greek, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.