Egg Tray Machine uses waste paper as raw material and it can produce different kinds of products according to your requirements, such as egg trays/dishes, egg cartons/boxes, fruit trays, coffee cup trays, wine bottle trays, industrial packages, electrical lining packing trays and so on. The different final products are decided by your market choice.

The egg tray machine moulds can be designed and made as customers’ requirement with samples.

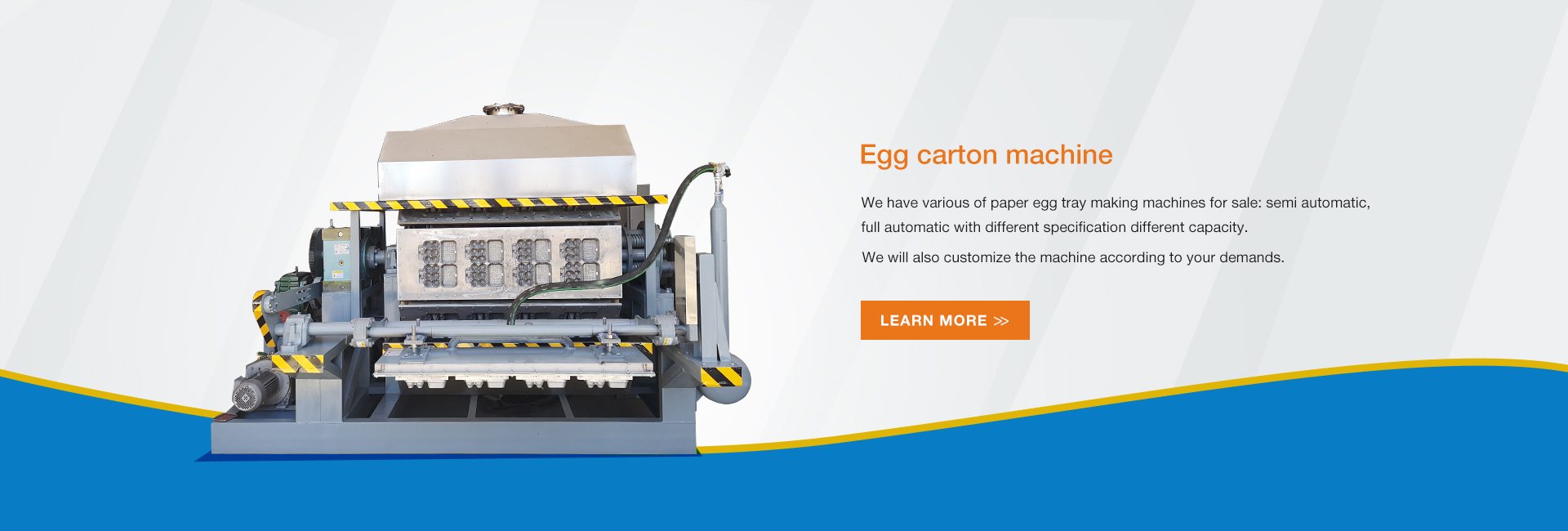

The production process flow:

Pulping system→Forming(Molding) system→Drying system→Stacking system

Working Process

Pulping system: It is the process of mixing the raw materials with water. Then you can get the slurry that is dried to form the egg trays.

Put all kinds of waste paper into the pulper, and after about 20 minutes of high-concentration stirring, the pulp is automatically transported to the pulp storage tank for storage and stirring. It is then transported to the pulp mixing tank by the pulp supply pump to be stirred to the required consistency, and then transported to the forming machine.

Forming(Molding) system: The process is that using negative pressure and vacuum absorption turn the slurry to egg trays. You can make egg trays, egg boxes, apple trays and so on with the paper tray machines by changing different moulds.

1. Forming machine: the pulp pump conveyed to the hopper of the forming machine is adsorbed onto the mould of the forming machine, the pulp is adsorbed to the mould of the forming machine by the suction of the vacuum system, and the excess water is sucked into the gas-water separation tank, and then the water pump draws the water into the pool for storage.

2. The mould of the forming machine absorbs the pulp and then forms, and then the finished product is taken out by the manipulator of the forming machine.

Drying system: It basically involves drying the wet semi-finished products by using egg tray drying line. Good drying process can lead to minimal losses of poorly-formed trays. There are metal and brick egg tray drying line.

1. The multi-layer metal drying line has six layers.

2. Heat source: coal, wood, natural gas, liquefied petroleum gas, diesel, biomass particles and other heat sources

3. The transmission mode adopts industrial transmission chain to drive the mesh plate transmission, and it operates in the drying line.

4. Advantages: reduce the cost of production site, save heat source, and save more than 30% heat source cost compared with traditional drying.

Stacking system: With stacker, we can squeeze large amounts of egg trays into together. Thereafter, egg trays will be packaged in the desired way.And it is convenient for conveying egg trays after packing.

Flow chart

Post time: Apr-22-2022