Free sample for Egg Tray Dryer Machine - Industrial Packaging Production Line – Pantao

Free sample for Egg Tray Dryer Machine - Industrial Packaging Production Line – Pantao Detail:

Equipment overview

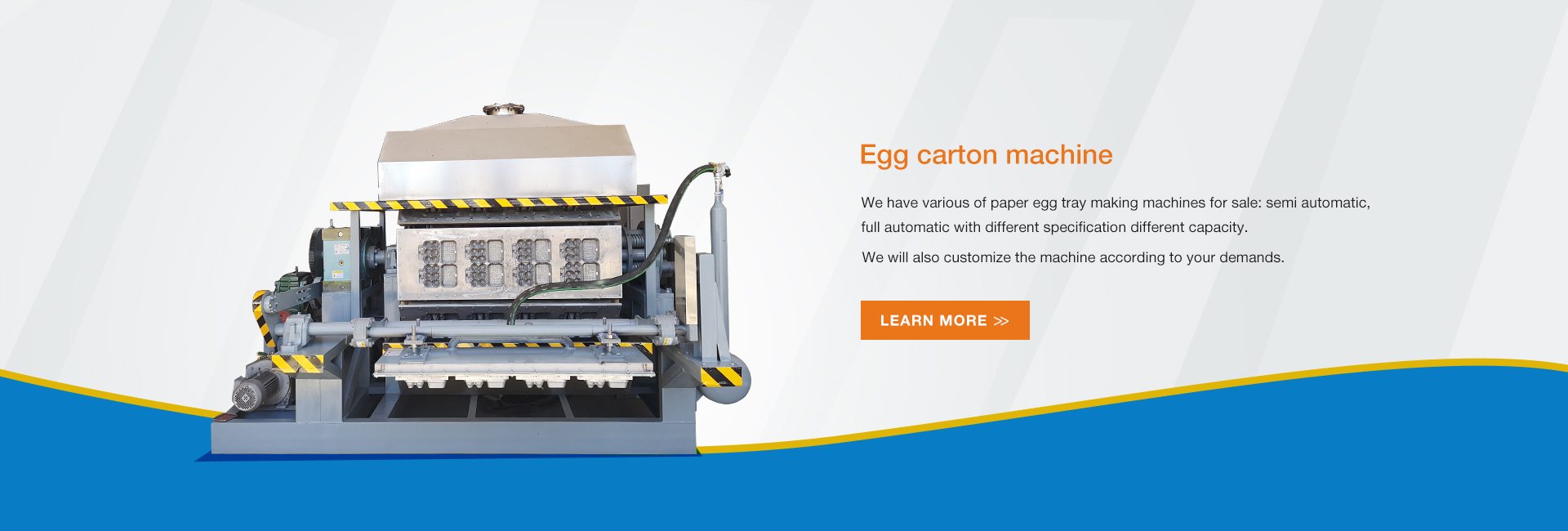

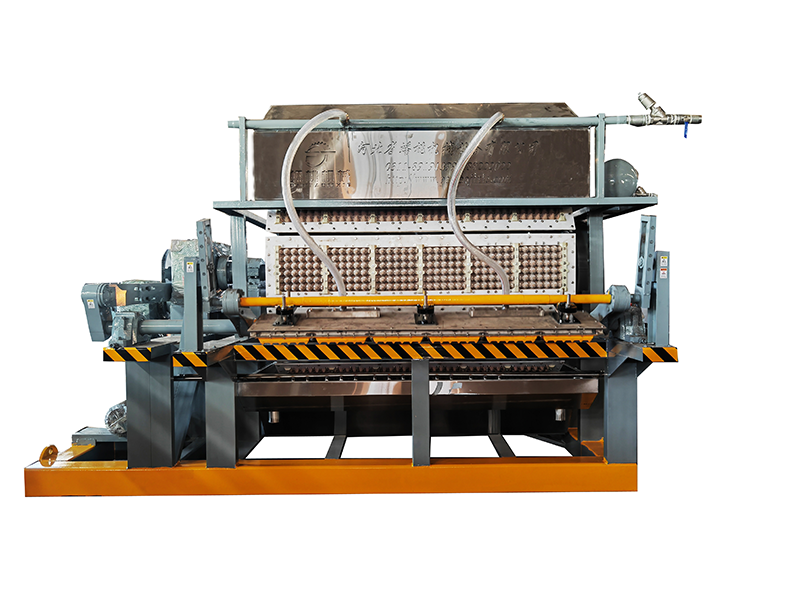

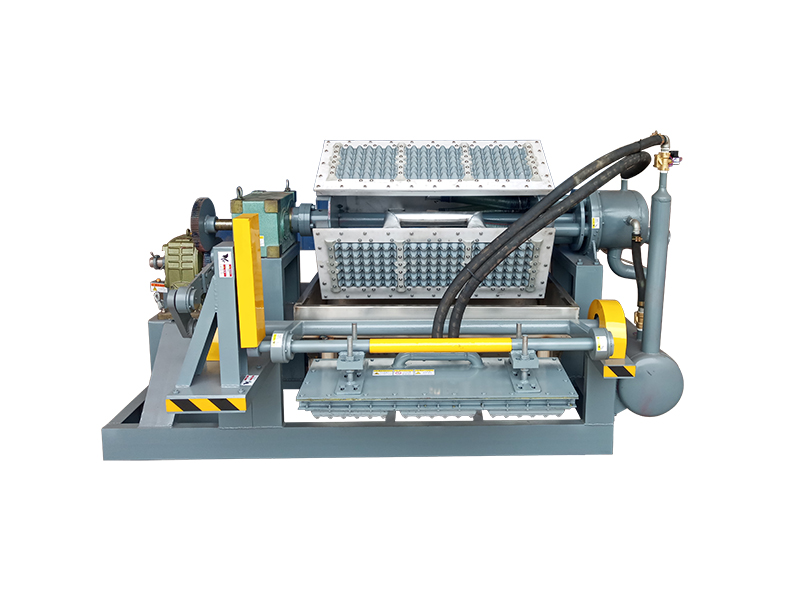

This equipment is a general-purpose machine for pulp molding products. The equipment consists of forming templates, transfer templates, air cylinders, PLC intelligent control electrical appliances, solenoid valves and other components.

YZ-GB500 pulp molding equipment is a single-station reciprocating equipment, mainly used to produce paper pulp molding products, such as egg trays, coffee cup trays, fruit trays, medical trays, electrical appliance lining packaging, and paper tray lining packaging with a height of less than 350mm.

The drying method is generally natural drying or trolley drying.

YZ-GB1000 egg tray pulp molding machine is a double-station reciprocating equipment, which is mainly used to produce paper pulp molding products such as egg trays, coffee cup trays, fruit trays, medical trays, electrical appliance lining packaging, and paper tray lining packaging with a height of less than 350mm. The drying method is generally natural drying or trolley drying.

Advantages

1. Energy saving

2. Flexible production

3. Low mould input

4. Easy operation and maintenance

Parameters

|

Parameters |

|||

| Model |

YZ-GB500(Single station) |

YZ-BG1000(Double station) |

|

| Template size |

400mmx1200mm 500mmx1200mm 600mmx1600mm 1200mmx1200mm 1450mmx1450mm Can be customized |

600mmx800mmx2 650mmx900mmx2 700mmx1000mmx2 Can be customized |

|

| Number of molds |

One plate forming mould& one plate transfer mould |

two plate forming mould& two plate transfer mould |

|

| Operating mode of forming machine |

Reciprocating slurry |

||

| Molding cycle |

5-8 times/minute |

||

| Power | 55-100kw | 55-100kw | |

| labour | 3-4 person/shift | 3-4 person/shift | |

| Control System | PLC intelligent system (programmable) | PLC intelligent system (programmable) | |

| Can produce product height |

≤350mm |

||

| Drying method | Natural drying |

Naturally air-dry the product through sunlight and natural breeze |

|

| dryer |

A:Trolley type traditional brick dryer B:Trolley type metal multi-layer dryer Heat energy can be used: coal, natural gas (LNG), diesel, liquefied petroleum gas( LPG), heat transfer oil, steam and other heat energy |

||

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for Free sample for Egg Tray Dryer Machine - Industrial Packaging Production Line – Pantao , The product will supply to all over the world, such as: Angola, Riyadh, Australia, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!