Bottom price Wet Pulp Paper Tray Machine Process - Pulp Molding Molds – Pantao

Bottom price Wet Pulp Paper Tray Machine Process - Pulp Molding Molds – Pantao Detail:

Mould

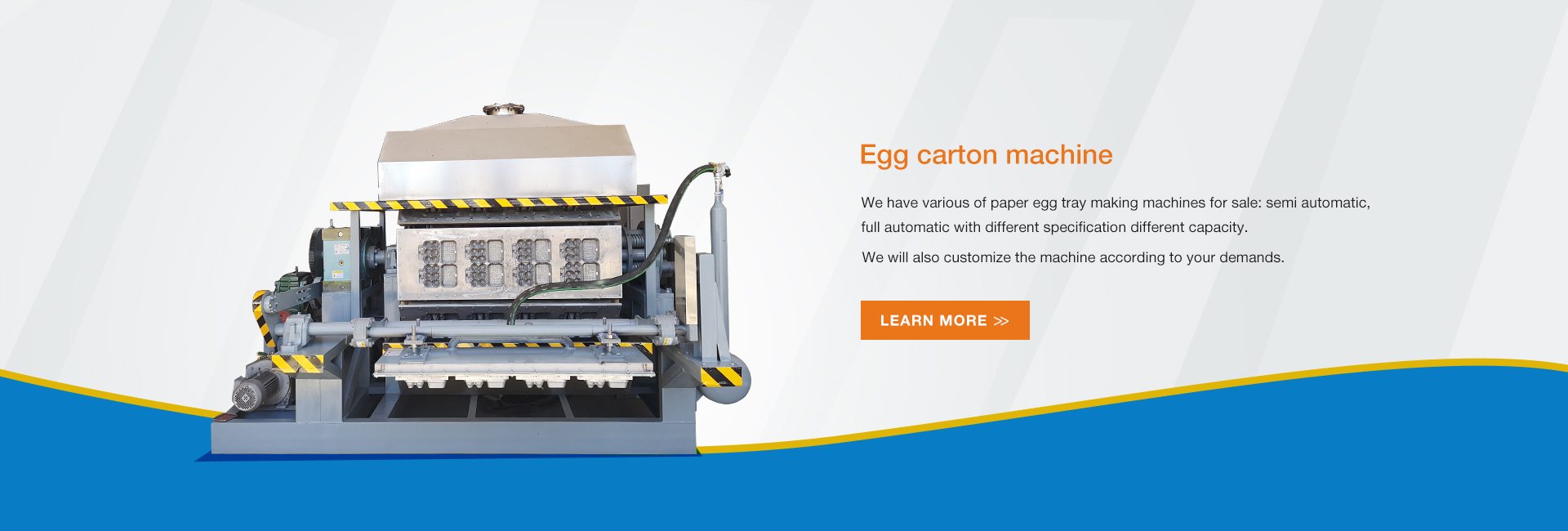

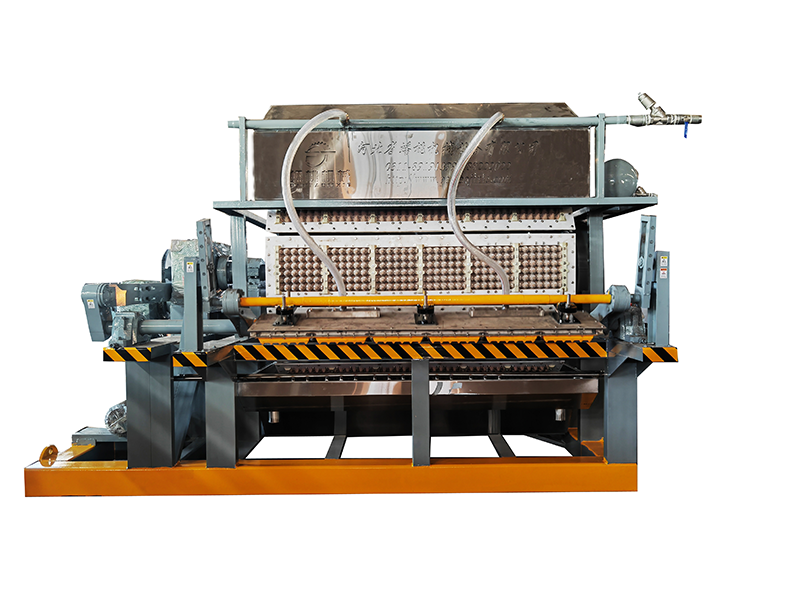

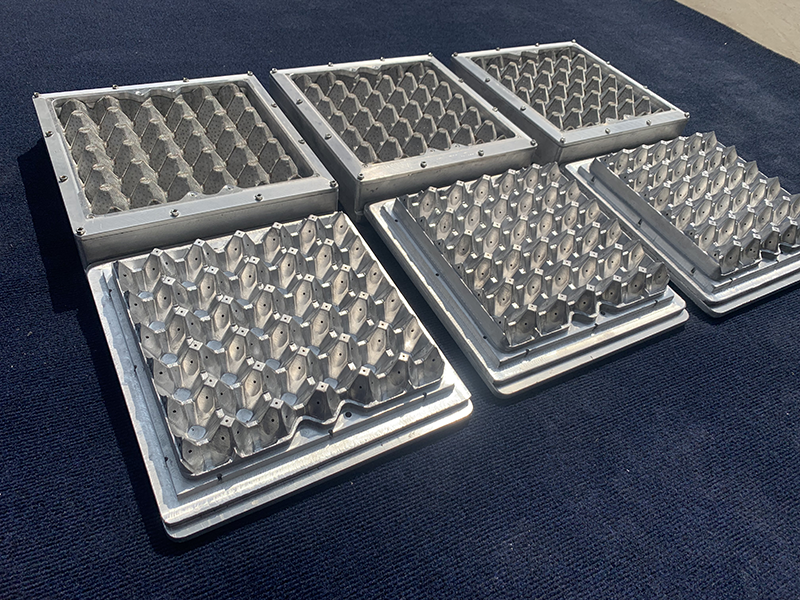

Environmental protection pulp industrial packaging mold workshop – the company has 3 professional industrial package mold designers and more than 20 technicians. The designers have been engaged in the research, design and production of paper tray molds in the Pearl River Delta of Guangdong for many years; they have rich experience in making industrial packaging paper tray molds;The packaging molds designed and produced for household appliances, handicrafts, porcelain and other products have the advantages of strong usability and reasonable design structure.; Can assist paper tray manufacturers from product packaging planning, paper tray product design to paper tray mold making, and post-production process tracking and other one-stop services. Our company produces egg tray molds (including aluminum egg tray molds, high-strength plastic egg tray molds, and copper egg tray molds), fruit tray molds (including aluminum fruit tray molds, copper plate stamping fruit tray molds, and copper fruit tray molds. ), egg carton molds (including 6, 10, 12, 15, 18, 25, 6 conjoined, etc.), shoe support molds, medical supplies paper trays (kidney-shaped trays, male and female urinals, etc. ), seedling cup holder mould, in addition to supporting various models (reciprocating machine, flip-type machine, rotary drum machine, etc.) which sell well in the domestic market, and are also exported to Russia, Australia, Malaysia, Kazakhstan, Egypt, India , Sudan, Brazil, Nigeria, etc. The company has become an important enterprise in modern environmental protection packaging technology, and is a solid partner for businesses committed to the environmental protection industry.

Environmentally friendly pulp tableware mold production workshop – our company has 3 designers who have been engaged in tableware molds since 1999, and have a relatively in-depth understanding of the process characteristics of tableware molds and the equipment requirements of various manufacturers; With the company’s modern production equipment, the production process adopts the production process of computer-aided design, computer programming, and one-time processing of the machining center, which ensures the accuracy, stability and versatility of production; the success rate of one-time mold test is more than 98%; the company’s mold debugging cycle is short, The mold quality and after-sales service have been recognized by many manufacturers in a timely manner, and a long-term cooperative relationship has been established; At present, dozens of tableware manufacturers across the country have provided pulp tableware molds with different production processes (automatic, semi-automatic) and heating methods (electric heating, steam heating, heat transfer oil heating).

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Bottom price Wet Pulp Paper Tray Machine Process - Pulp Molding Molds – Pantao , The product will supply to all over the world, such as: Morocco, Gabon, Jakarta, With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!