Best-Selling Paper Plate Forming Machine - Paper Pulp Molding Machine One side (600-1700 pcs/hr) – Pantao

Best-Selling Paper Plate Forming Machine - Paper Pulp Molding Machine One side (600-1700 pcs/hr) – Pantao Detail:

Equipment overview

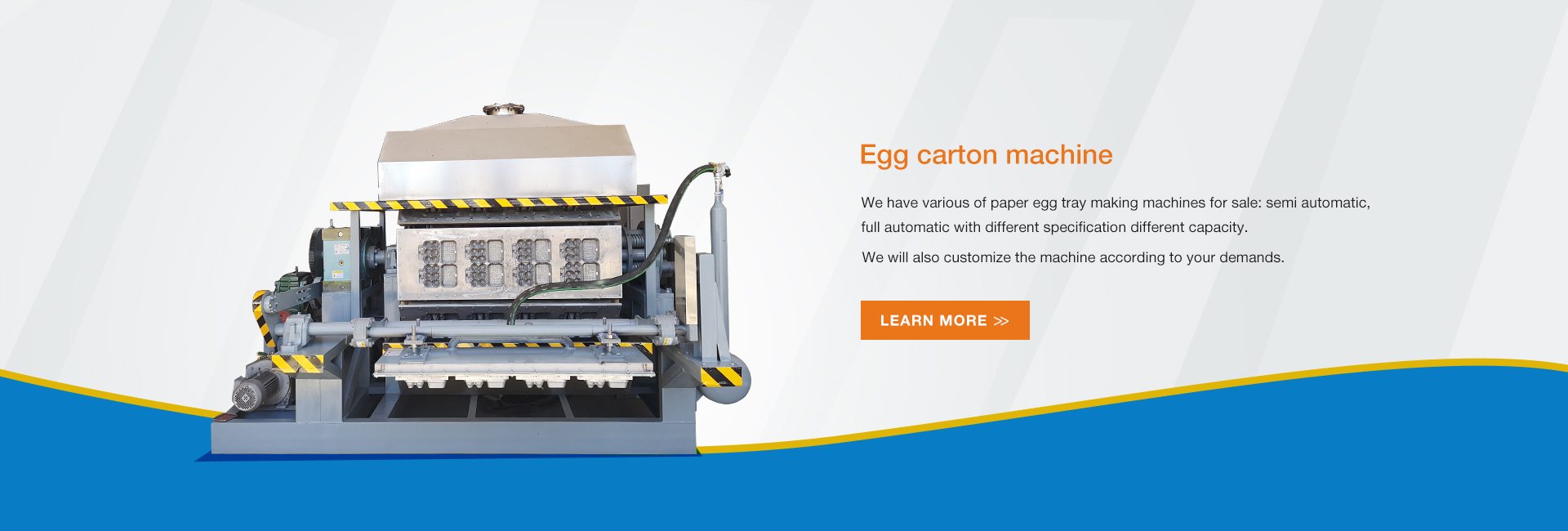

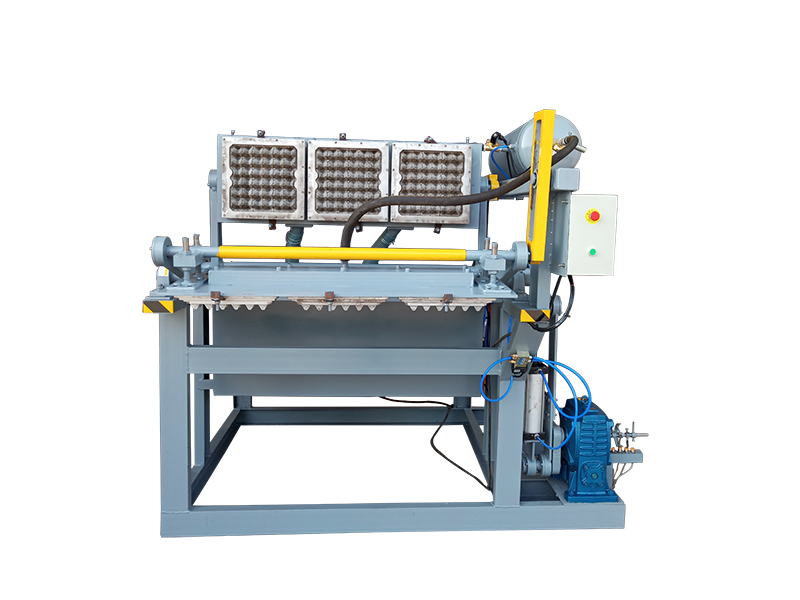

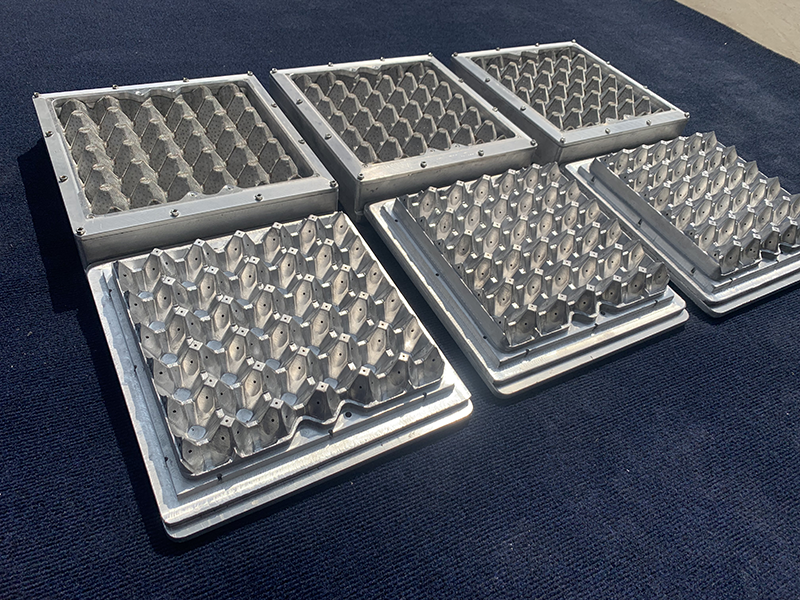

This equipment is a flip-type molding machine, which is composed of molding templates, transfer templates, worm reducers, motors, intelligent control electrical appliances, cylinders, solenoid valves and other components. The worm reducer is driven by the transmission motor to make the equipment template run at 90 degrees. This equipment was independently developed and manufactured by our company in 2008 and is now widely used in the egg tray and paper tray industries.

The automatic flip type egg carton production line is composed of pulping system, forming system, drying system and stacking system. It is specialized in producing 6, 10, 12, 15 and 18 egg carton products. Using waste carton paper, waste newspapers, corrugated papers, scraps and other waste paper as raw materials, preparing a certain concentration of slurry by hydraulic disintegration, filtration, water injection and other processes, through the molding system on the special metal mold by vacuum adsorption, a wet blank is formed, then dried on a drying line, hot-pressed and stacked.

Advantages:

1.This machine can produce egg tray, egg box, bottle tray, paper shoe stretcher, paper cup holder.

2.Suitable for small output with flexible and easy operation.

3.Small investment, suitable for new customer.

Parameters

| Model | YZ-F500(1-2) | YZ-F1000(1-3) | YZ-F1500(1-4) | YZ-F1700(1-5) | |

| Capacity/hour | 600pcs | 1000pcs | 1500pcs | 1700pcs | |

| Template size | 850MMX410MM | 1250MMX410MM | 1650MMX410MM | 1950MMX410MM | |

| Number of molds | 2 boxes | 3boxes | 4boxes | 5boxes | |

| Operating mode of forming machine |

Inverted suction molding |

||||

| Molding cycle |

6Times/minute |

||||

| Power | 33kw | 33kw | 42kw | 50kw | |

| labour | 3 person/shift | 3person/shift | 3person/shift | 4person/shift | |

| Paper | 40kg/hr | 85kg/hr | 100kg/hr | 119kg/hr | |

| Water | 120kg/hr | 255kg/hr | 300kg/hr | 357kg/hr | |

| Product height that can be produced |

80mm |

||||

| Drying method | Natural drying |

Naturally air-dry the product through sunlight and natural breeze |

|||

| dryer |

A:Traditional brick dryer B:Metal multi-layer dryer Heat energy can be used: coal, natural gas (LNG), diesel, liquefied petroleum gas( LPG), heat transfer oil, steam and other heat energy |

||||

| 1. The capacity of the equipment is calculated based on the production of 30 egg trays with a size of 300*300mm and a dry tray weight of 70g.2. Various specifications of equipment can be customized according to customer requirements. | |||||

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for Best-Selling Paper Plate Forming Machine - Paper Pulp Molding Machine One side (600-1700 pcs/hr) – Pantao , The product will supply to all over the world, such as: California, Hamburg, Cancun, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.